The technical problem

Creating a conical hole is a particular challenge. Creating a hole of this geometry in a material such as steel makes the relative tool even more complex to design and manufacture.

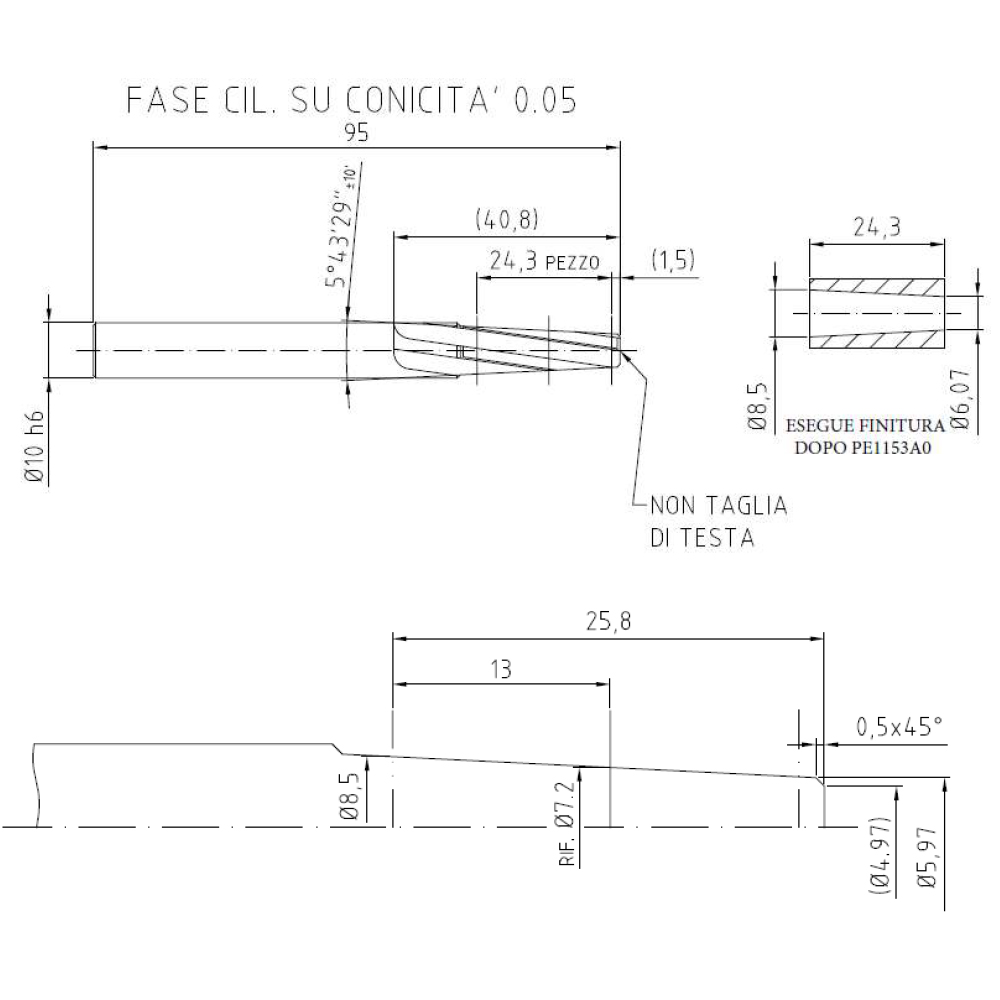

In this specific case, the client needed to create a 5° 43’ 30’’ conical hole, as per the relative design.

Unfortunately, neither the first or the successive three attempts were able to drill a hole; the drill broke every time, even with different coatings and geometries.

The MadTools solution

After having carefully studied the problem, the solution we found finally produced the desired result. We divided the operation into two phases, roughing and finishing:

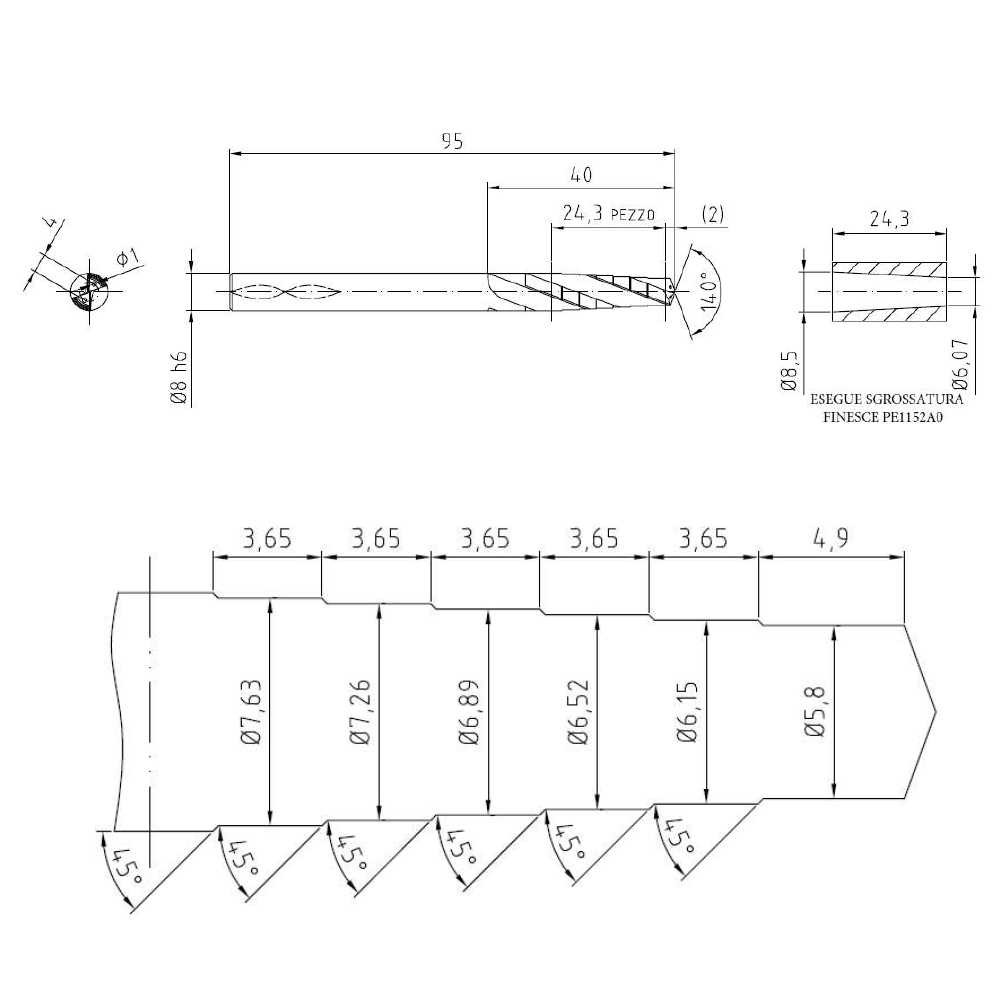

- For the roughing, we designed a “multistepped drill” that prepares the material for the conical drill.

- We designed a conical drill for the finishing stage.

Technical explanation

This solution was adopted to reduce the contact surface between the tool and the item.

Roughing with the “multistepped” drill allows for:

- a reduction in the cutting force in relation to the quantity of chip removed;

- the more gradual removal of material by the conical drill.

Problem solved!