Interchangeable heads have a significant impact on workshop costs.

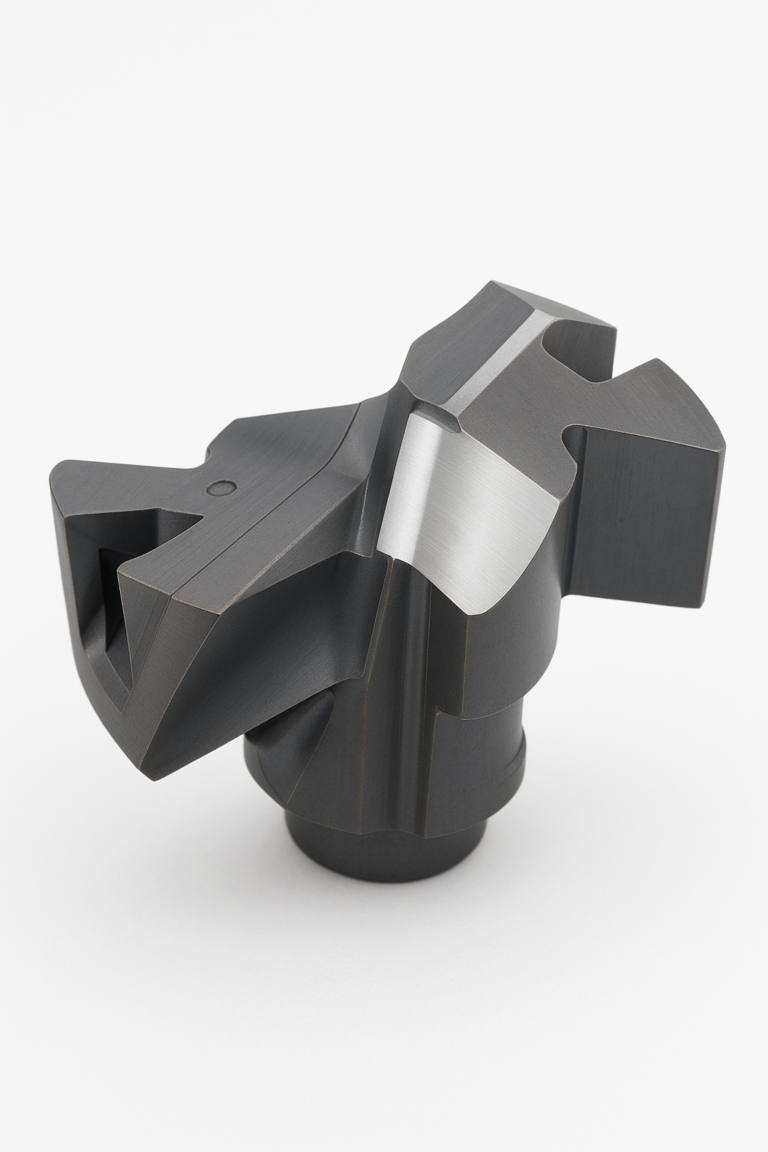

In precision drilling, solid carbide heads (Iscar, Kennametal, Tungaloy, Sandvik, etc.) offer high performance… but at a price ranging from €36 to €180 per piece.

Regrinding can turn this expense into a tangible operational advantage.

When savings are real

The comparison is straightforward:

• new head → €36–180

• regrinding → 35–45% of the original price

Result: up to 65% net savings.

Not all heads are suitable for regrinding.

Minimum conditions:

• diameter ≥ 8 mm

• no structural damage (deep chipping = scrap)

• max. 3 regrinding cycles per piece

Technical constraints

Regrinding is effective only if:

• material removal on the head height does not exceed 0.6 mm

• original geometries are maintained (angles and reliefs as designed)

• PVD coating is optimized: in some cases performance even exceeds new tools

A real case: from failure to €85,000 savings

A Spanish automotive company used 2,000 heads Ø16.2 and Ø17.2 per year.

The first regrinding attempt, entrusted to the wrong supplier, led to:

• roughness worsening from Ra 0.8 μm to Ra 3.5 μm

• tool life reduced by 70%

• uncontrolled vibrations on the machine

Cause: cutting edges too aggressive.

Adopted solution:

• controlled edge honing (0.05 mm)

• coating specific for alloy steels

• test on 50 samples before full production

Result: stable roughness at Ra 0.9 μm, performance equal to new, and annual savings of €85,000.

How to choose the right partner

The difference lies in competence. Key requirements:

• preliminary economic feasibility analysis

• standardized and traceable process

• maximum three regrinding cycles to ensure consistent quality

Conclusion

Regrinding is not a “low-cost fallback,” but a precise industrial strategy.

Applied correctly, it delivers new-tool quality at one-third of the cost.