The technical problem

In order to increase productivity, many companies need to increase feed rate.

An increase in feed rate can lead to an increase in stress on the tool. Over time, this can lead to the tool breaking. Tool breaks are particularly significant problems with holes of a depth of at least 5xD

Is it possible to change the geometry of a tool in order to allow feed rate to be increased?

The MadTools solution

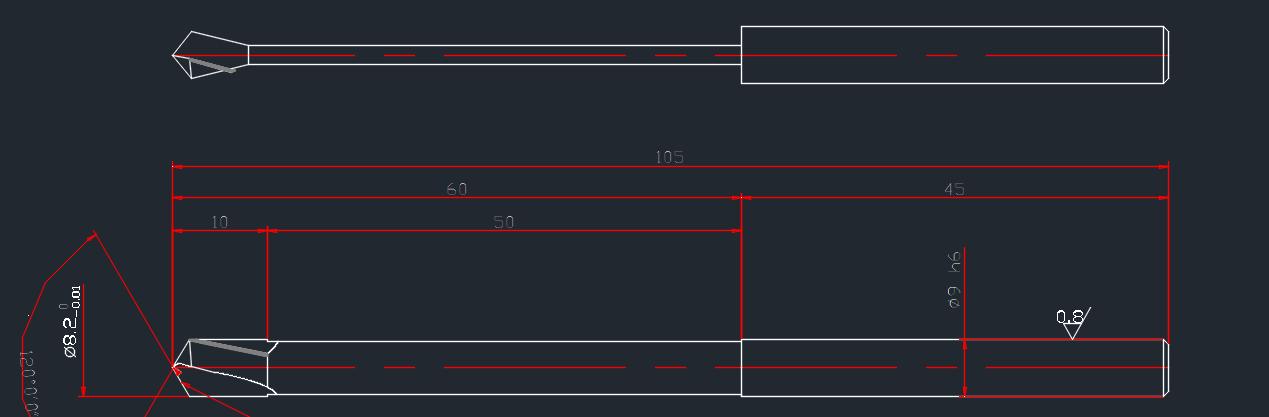

After numerous attempts, we came up with a solution: the Thor drill. This drill is madeto combine the distinctive features of a twist drill and a gundrill. In particular:

- The initial part is built like a twist drill.

- The ejection section: one part is twist, and the other part is gundrill.

Compared to a standard drill, this means that the Thor drill:

- has increased drilling capacity.

- has increased chip ejection capacity.

- has higher stress resistance.

Technical explanation

The Thor drill allows operators to increase feed rate for two main reasons:

- The initial twist part of the drill increases drilling capacity

- The gundrill ejection section facilitates chip ejection