Why cycle time is critical in multi-spindle lathes. In productions of tens of thousands of parts per day, every second of cycle translates into thousands of parts more or less. In mechanical multi-spindle lathes, the rule is clear: cycle time depends on the slowest operation. But often it’s not just one position creating the bottleneck: chip management can also drastically slow down production.

Case study: cycle time reduced from 18 to 12 seconds

Sector: faucets

Material: lead-free brass (CW510L).

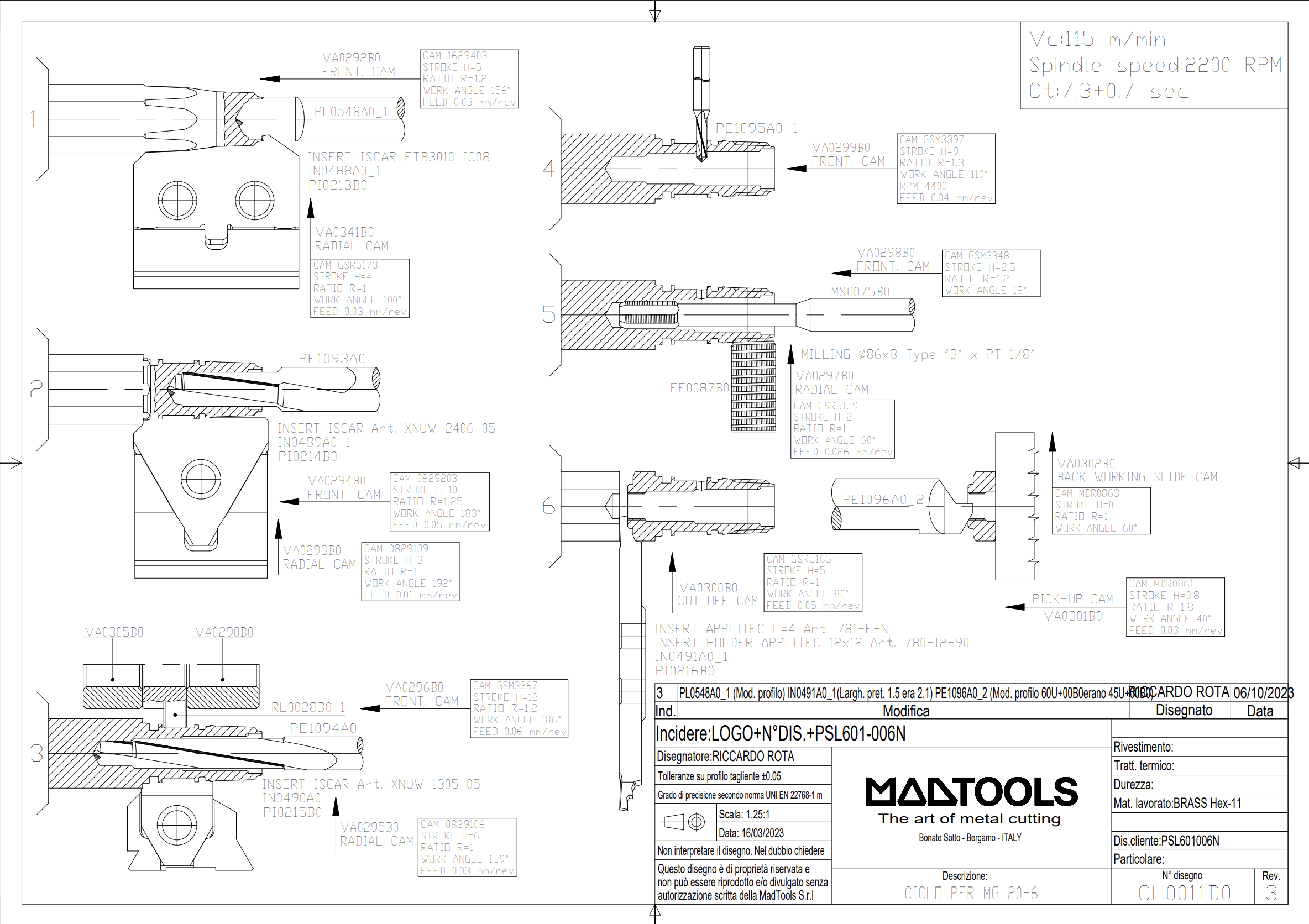

Machine: mechanical multi-spindle lathe Gildemeister, 6 positions.

Problems found:

- Critical position: roughing + finishing required 18″, versus a target of 11″, blocking the entire line.

- Long continuous chips: lengths of 60–80 cm that tangled, causing machine downtime of up to 2 hours per shift.

MadTools solutions

- Cycle rebalancing – the critical operation was split: 10″ roughing on one spindle and 8″ finishing on the next. Bottleneck removed.

- Custom combined tool – designed to integrate grooving and facing operations, freeing one position on the multi-spindle and improving workload distribution.

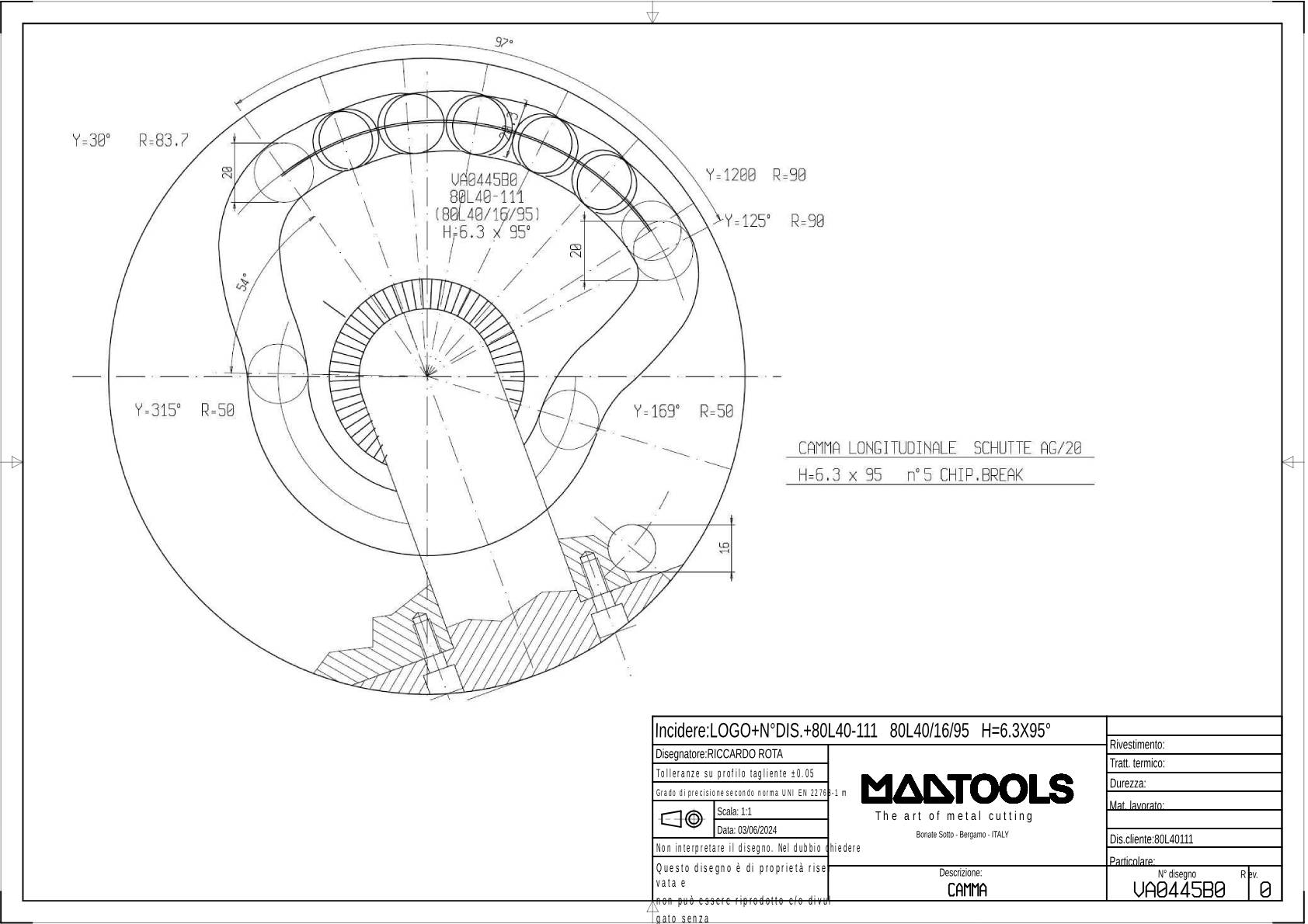

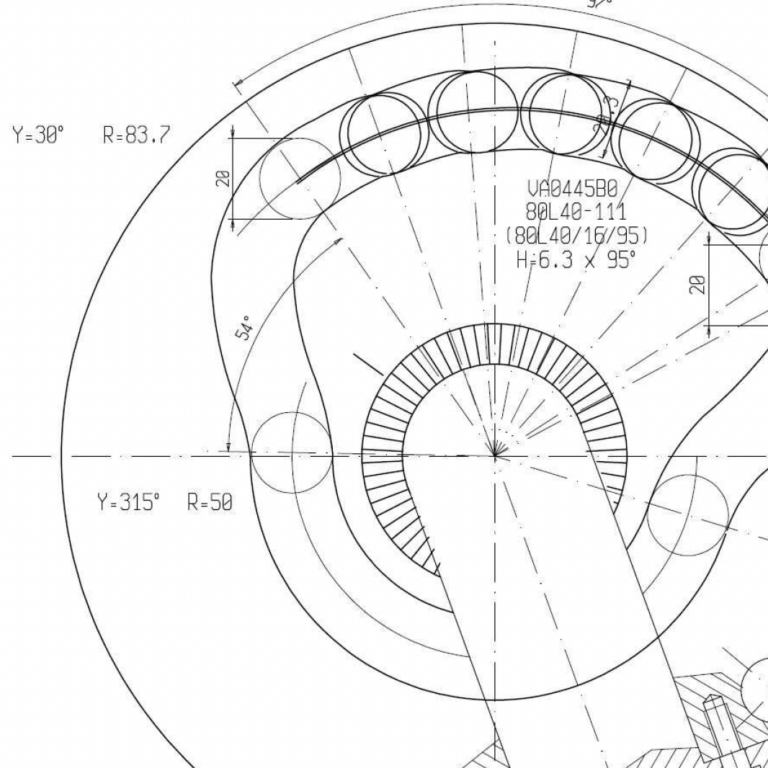

- Dedicated chipbreaker cam – developed for lead-free brass CW510L: chips broken to 8–12 mm, tangling eliminated and machine downtime reduced to zero.

Results achieved

- ⏱ Cycle time: from 18″ to 12″ (–33%)

- 🛠 Machine downtime: eliminated

- 📈 Production: from 4,400 to 7,200 parts/day (+64%)

Conclusions

The case demonstrates that in mechanical multi-spindle lathes, improvement doesn’t come from a single action but from an integrated approach: cycle rebalancing, custom tools that free up positions, and optimal chip management.

👉 Contact MadTools technicians for an analysis of your production cycles and the design of dedicated tools.