The choice between brazed tool and mechanical clamping determines production costs, cycle times and final quality. Here are the technical-economic criteria for making the right decision.

The choice problem

Anyone who works with bars, prismatic pieces, or custom shapers knows the dilemma: purchase an economical but rigid brazed tool, or a more expensive but flexible mechanical system?

The decision impacts 2 critical factors:

- Operating costs: downtime and replacement management

- Dimensional quality: precision and surface finish

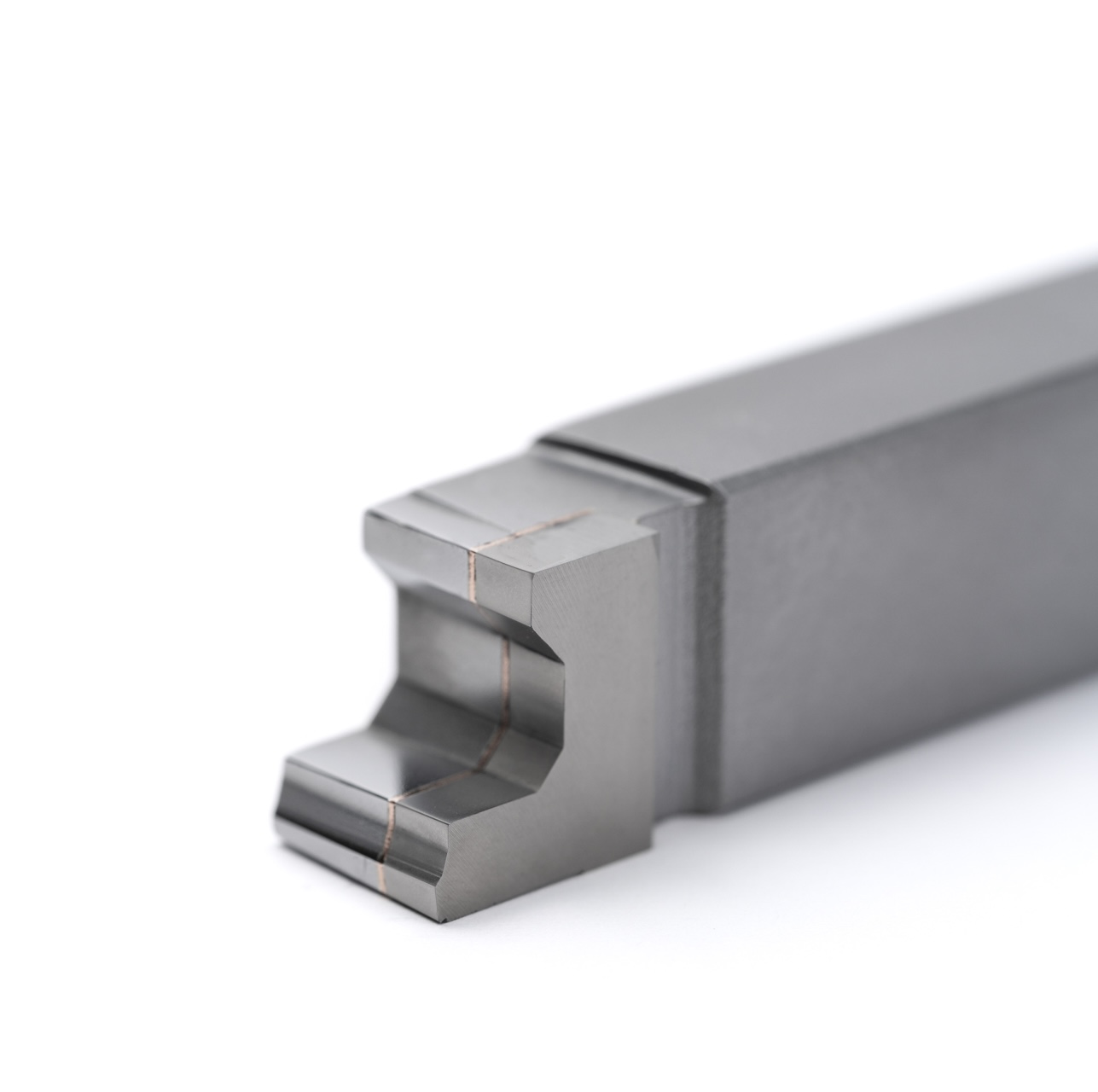

Brazed tool

High-temperature brazing (>450°C, DIN ISO 857-2) creates a permanent metallurgical bond between insert and tool body.

Technical characteristics:

- Maximum rigidity: monolithic without joints

- Custom geometry for specific applications

- Compact section: usable in grooves <3mm

- Cost: 45-95€ per finished tool

Operating limitations:

- End of life = mandatory machine downtime (5-10 minutes)

- Risk of thermal deformation above 55-60 HRC

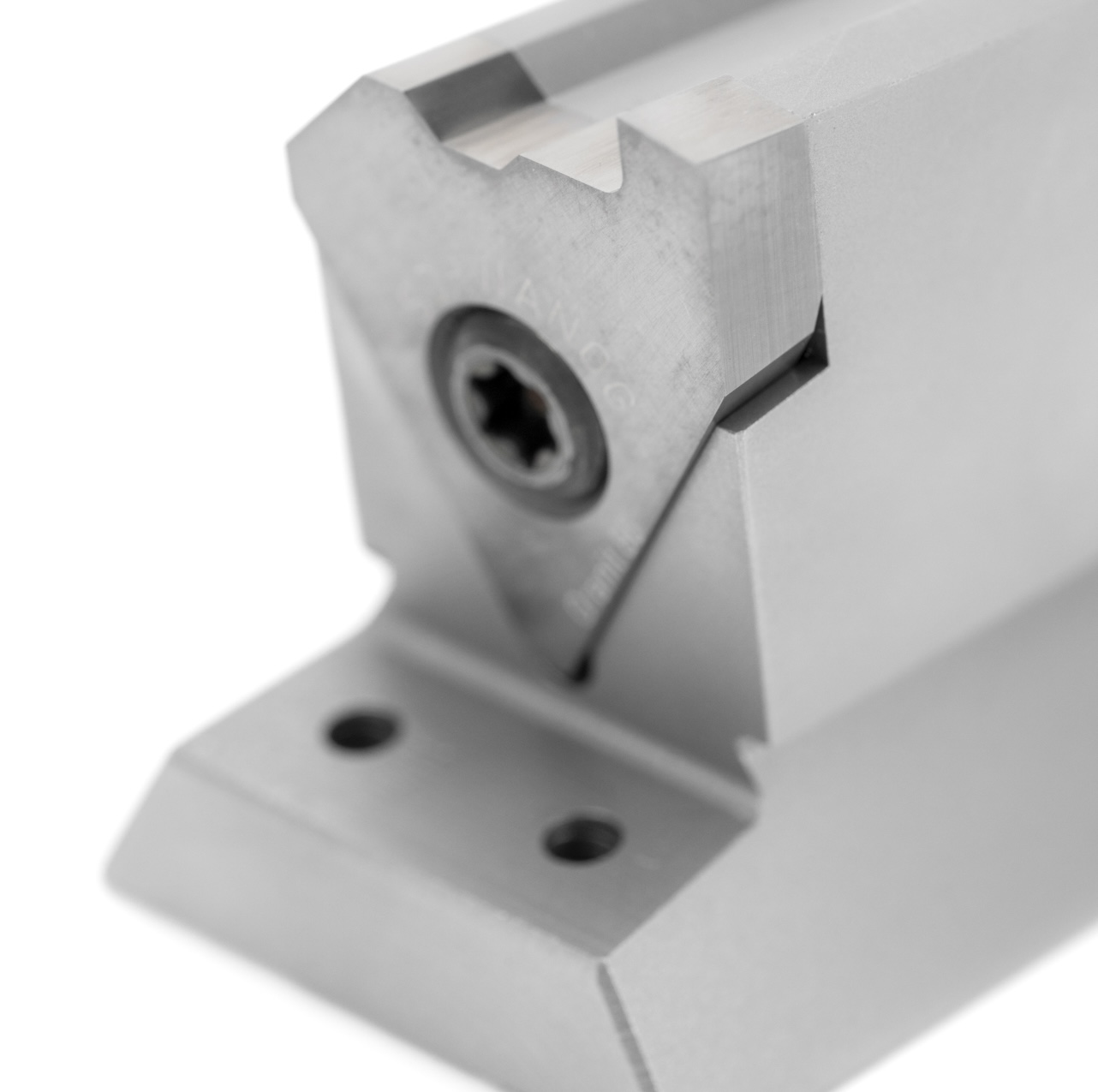

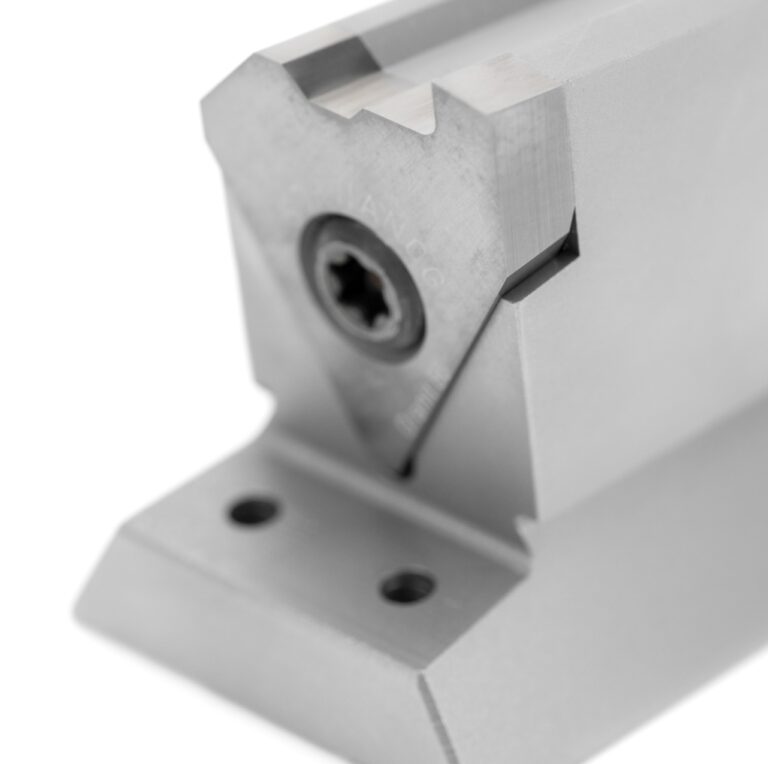

Mechanical clamping tool

System with interchangeable inserts, mechanically locked to the tool holder.

Technical characteristics:

- Insert change: 30 seconds vs 8 minutes for brazed

- Grade flexibility: same base, different inserts

- Investment: 70-120€ insert holder + 45-85€ per insert

Operating limitations:

- Larger section: problematic below 3mm

- Higher initial investment

- Requires optimal clamping and cooling

Selection criteria

| Parameter | Brazed | Mechanical clamping |

| Batch volume | <500 pieces | >1000 pieces |

| Geometric complexity | Critical profiles, narrow grooves | Simpler geometries |

| Material hardness | <55 HRC | Any hardness |

| Production type | Small batches | Continuous series |

| Priority | Maximum precision | Operating flexibility |

Economic analysis

Example: boring Ø8mm x 25mm on C45 steel, batch 1600 pieces Average tool life: 400 pieces for brazed, 400 pieces for mechanical insert

Brazed option:

- Tools required: 1600÷400 = 4 tools

- Tool cost: 4 × 80€ = 320€

- Total changes: 3 changes (first already mounted)

- Lost time: 3 × 8 minutes = 24 minutes

- Total cost: 320€ + (24 min × machine downtime cost)

Mechanical option:

- Insert holder: 95€ (one-time investment)

- Inserts required: 1600÷400 = 4 inserts

- Insert cost: 4 × 55€ = 220€

- Total changes: 3 insert changes

- Lost time: 3 × 0.5 minutes = 1.5 minutes

- Total cost: 315€ + (1.5 min × machine downtime cost)

Result: using 4 inserts instead of 4 brazed tools and considering machine downtime cost, the insert holder has already paid for itself. From the fifth insert onwards, the advantage of mechanical clamping will continue to increase.

Operating conclusions

The choice depends on objective parameters:

Brazed when:

- Low volumes don’t justify insert holder investment

- Complex geometries require absolute rigidity

Mechanical clamping when:

- High volumes amortize initial investment

- Multi-material production requires flexibility

- Machine time is an important factor

The optimal choice emerges from combined analysis of technical, economic and operational constraints specific to the application. Economic calculations are decisive only when both solutions are technically valid.