Did you know that with the transition to lead-free brass, many turning workshops are seeing a 10% increase in non conformity and a 25% increase in tool wear?

The absence of lead results in long, hard chips that subject both tools and processes to stress.

Here are 4 possible solutions to avoid this problem:

- Specific clearance and rake angles

If the machine is not sufficiently rigid, the clearance and rake angles need to be reduced. - Coolant channels

Targeted cooling limits deformation and can also reduce swarf by up to 15%. - Increased drilling diameters

“Lead-free” brass tends to shrink in the final stages of the machining process: an increase in diameter of a few hundredths can avoid undersized holes and tolerance defects. - High-rigidity chucks

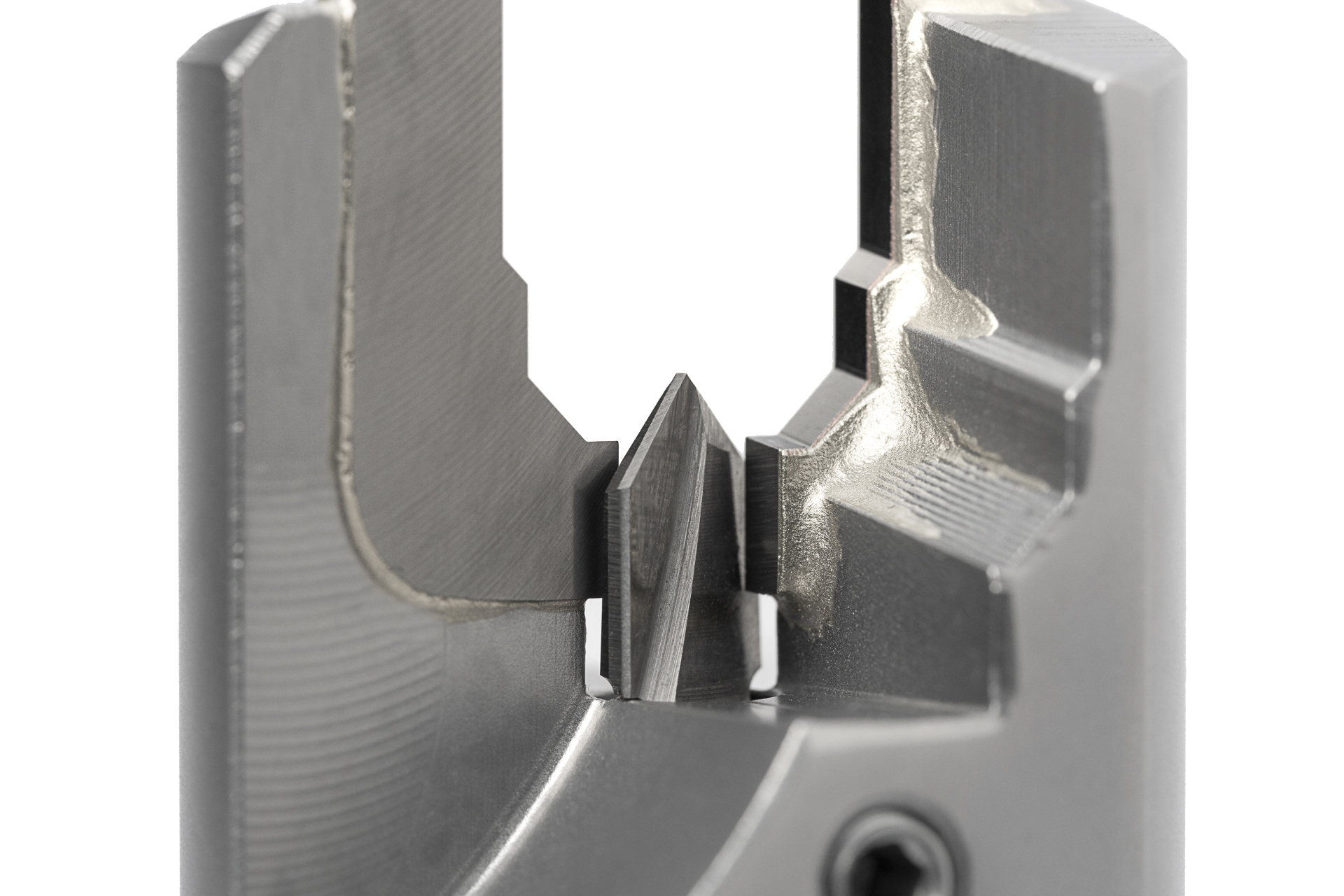

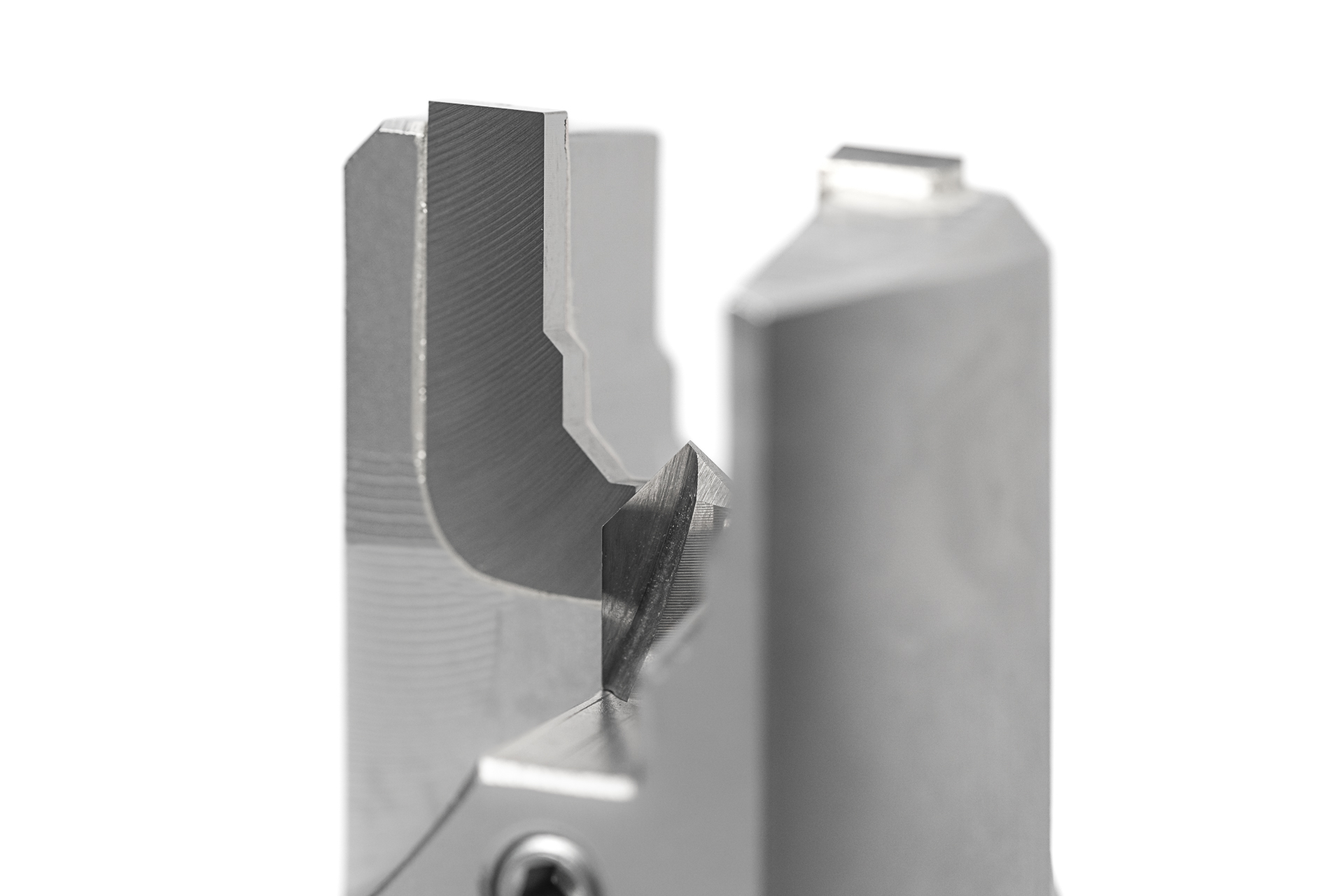

Using high-rigidity chucks allows us to produce tools with more wear-resistant materials.

At MadTools, our extensive experience in processing lead-free brass means we can design tools that guarantee:

- lower levels of nonconformity

- lower costs per item